Tel:86-0310-6090111

Mobile:86-13111386563

Fax:86-0310-6090111

Email:hdzyjx@hdzyjx.com

When the hydraulic hammer is installed and connected with the hydraulic excavator or other construction machinery, the working pressure and flow of the hydraulic system of the main engine must meet the requirements of the technical parameters of the hydraulic hammer; P” The port is connected with the high pressure oil circuit of the main engine; A” The port is connected with the oil return circuit of the main engine.

1)The working temperature of the hydraulic breaker is 50-60 ℃, and the height of the hydraulic breaker shall not exceed 80 ℃. Otherwise, the load of hydraulic hammer should be reduced.

2)The working medium used by the hydraulic hammer is usually the same as the oil used by the hydraulic system of the main engine. Yb-n46 or yb-n68 anti-wear hydraulic oil is recommended in general areas, and yc-n46 or yc-n68 low temperature hydraulic oil is recommended in cold areas. The filtration accuracy of hydraulic oil is not less than 50micro; m。

3)New and repaired hydraulic hammers must be refilled with nitrogen at a pressure of 2.5; plusmn; 0.5MPa。

4)Calcium base grease or compound calcium base grease must be used for lubrication between the drill rod handle and the guide sleeve of the cylinder block, and the hydraulic hammer accessories shall be filled once per shift.

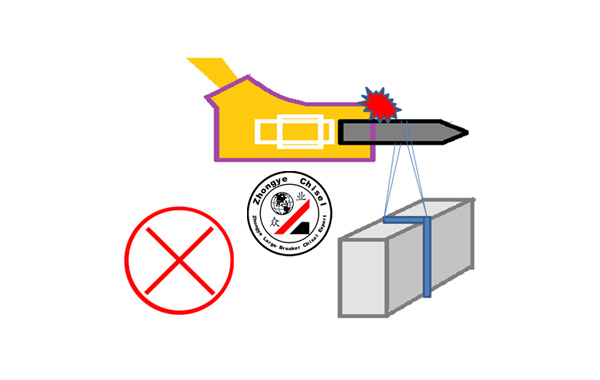

5)When the hydraulic hammer is working, the drill rod must be pressed on the rock, and a certain pressure must be maintained before the hammer is started. It is not allowed to start in the suspended state.

6)It is not allowed to use the hydraulic hammer as a crowbar to avoid breaking the drill rod.

7)When using, the hydraulic hammer and the rod should be perpendicular to the working face, and the radial force should not be produced